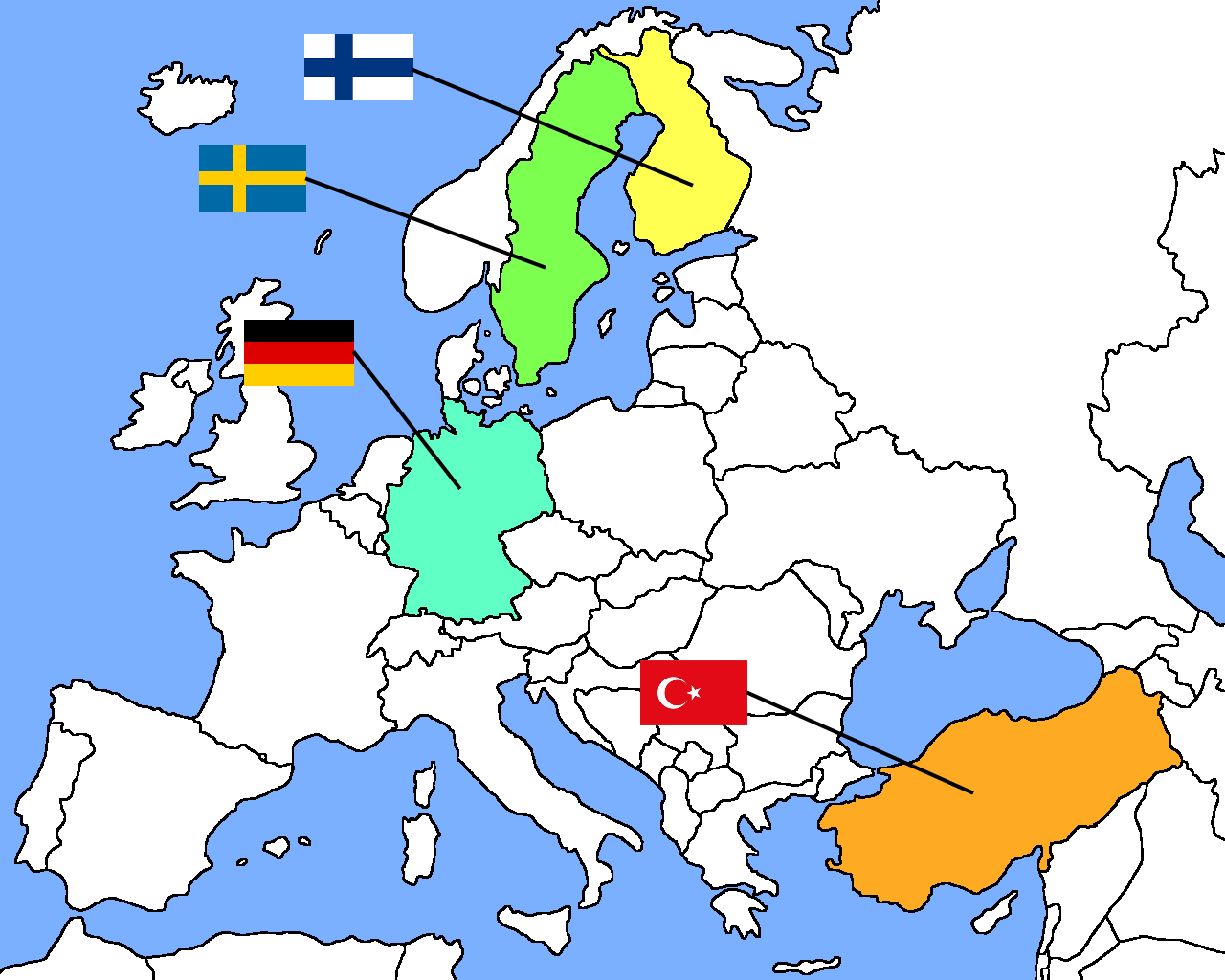

Partner countries

Motivation

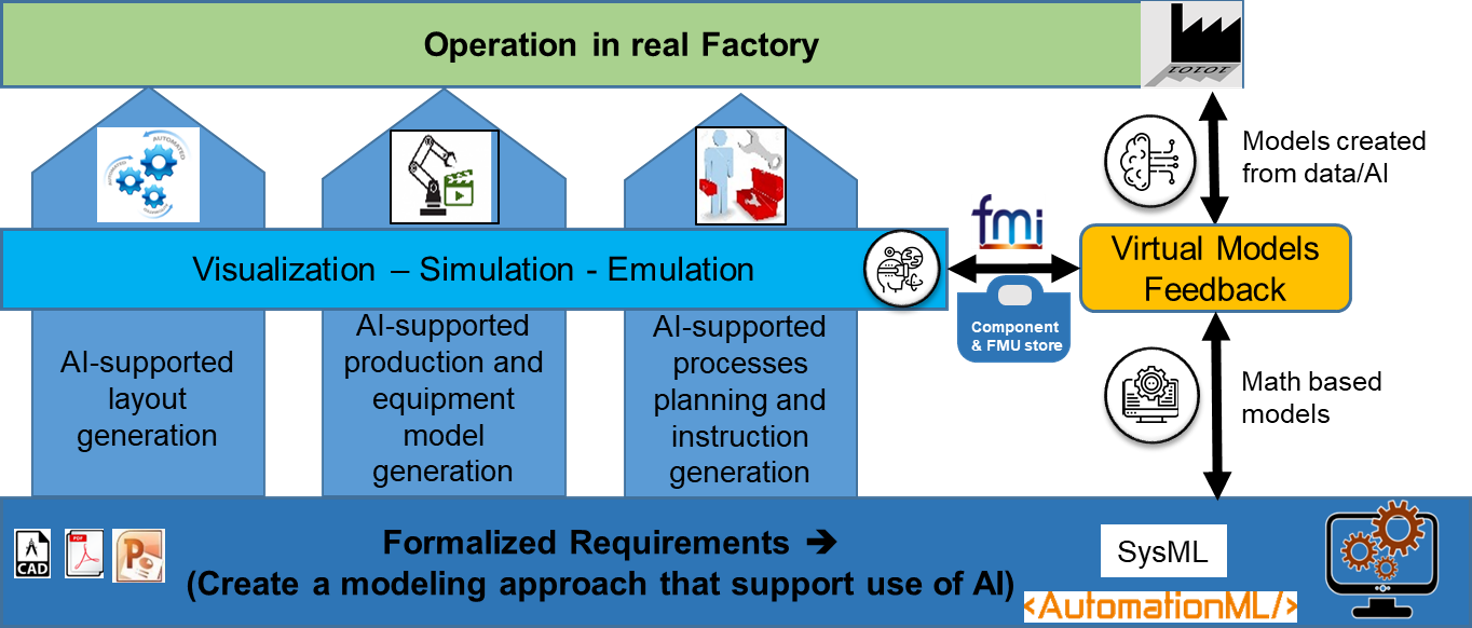

The goal if AITOC is to develop an integrated toolchain for manufacturing engineering that supports decision-making in early phases. To achieve this, the toolchain will support the formalisation and automated analysis of requirements, the computer-aided generation of process plans, simulation models and instructions and the softwaresupported generation of layouts. In all of these dimensions, Artificial Intelligence will be utilised in expert systems and simulations based on data from existing solutions. The interoperability of engineering tools is also in focus and will be developed using standardised neutral data formats.

Countries

The AIToC project consists of four national consortiums, Sweden, Germany, Finland and Turkey. The goal if AITOC is to develop an integrated toolchain for manufacturing engineering that supports decision-making in early phases. To achieve this, the toolchain will support the formalisation and automated analysis of requirements, the computer-aided generation of process plans, simulation models and instructions and the software supported generation of layouts. In all of these dimensions, Artificial Intelligence will be utilised in expert systems and simulations based on data from existing solutions. The interoperability of engineering tools is also in focus and will be developed using standardised neutral data formats.

Germany

The German consortium will benefit from a strong international consortium working in several domains with different industrial use cases. Sharing knowledge related to different technological solutions using artificial intelligence will be the base for optimizing engineering tools and for common standardization activities. The German consortium is composed of partners supporting the overall value chain for planning, simulating and optimizing manual and automated production processes (use -cases in production equipment manufacturing and bus & coach manufacturing).

Daimler EvoBus

Daimler Buses is one of the world leading bus & coach manufacturers with plenty of plants in Europe and worldwide. Daimler AG, the German coordinator, acts from a planning and simulation end user’s point of view. Daimler plans to industrialize the AIToC solutions as it fits to the internal vison towards a Digitalized Manufactory. Success shall be ensured through direct involvement in all WPs. Direct involvement in the novel AIToC technologies will result in higher efficiency of planning and simulating of manual processes, which will give a chance to further differentiate from competitors.

DFKI

DFKI is one of the biggest research centers for artificial intelligence worldwide. The involved DFKI research group already achieved international excellence in motion synthesis for virtual characters as well as for Artificial Intelligence technologies for planning and scheduling.

TWT GmbH Science & Innovation

TWT GmbH Science & Innovation is offering scientific and development services to its customers. While TWT already has a strong technological base in the context of requirements engineering, simulation technologies and related AI methods, the AIToC project bears a significant risk, due to the high ambition of the technological advances. Furthermore, TWT hopes to further enter the market of production planning tools and technologies, which promises further expanding its business, but at the same time involves multiple risks. Through the AIToC project, TWT will be able to mitigate these technological and business -related risks, through strong national and international collaboration.

Raumtänzer

Raumtänzer GmbH provides solutions for humans working in modern industry environments. AIToC will allow Raumtänzer to explore, how the design of instructions for augmented reality devices can be optimized by incorporating knowledge about instructability from early in the specification and planning process. The results of AIToC are expected to scale in other business areas of Raumtänzer, such as chemical engineering and healthcare.

ifak

IFAK e. V. is a well-known research and development partner of large and medium sized industry in the domain of automation for about 20 years. The applicability of Artificial Intelligence technologies in engineering tools, e.g., for production planning, has not yet been investigated. Furthermore, the use of AI to support the automatic evaluation of the target/actual comparison of the behavior of the production system is unsolved. IFAK intends to provide these technological achievements towards other potential customers from automation industry.

EKS

For EKS InTec, the advantages from AIToC results are to achieve a higher level of detail for the virtual commissioning components as well as modelling of these components becomes no longer necessary. This in combination with a standard package format offers EKS InTec the opportunity to enhance current engineering process according to labour efficiency. It is expected that this will have positive influence on the engineering service business.

Software AG

Software AG: Results and knowledge gained from the project will be directly used to improve the existing tool-chain within R&D but also foster the acquisition of customer projects in the problem domain. This project is hence considered as a competitive advantage that will improve market competitiveness through the envisaged technology and tools. We further intent to share results using cook-books and customer success stories. Along with each success we share with Software AG’s sales and pre-sales teams the targeted solution, the market and the customer that could eventually test configure the solution before licensing will occur.

RealVirtual.io

RealVirtual.io gmbH is a start-up company which was founded based on results of the ENTOC project. The software game4automation is a development framework for visualization, virtual commissioning, virtual and augmented reality in the domain of automation. It is planned to extend the software with artificial intelligence functionalities and to combine it with solutions for the simulation of manual processes.

Isb innovation software businesses

For isb innovative software businesses GmbH, the added value is to extend the current focus of behavioral modeling with artificial intelligence to other industries and topics and to improve the toolchain for the selection of models. The project is intended to support standards such as AutomationML, FMU or MMU.

Finland

The Finnish consortium is composed of partners supporting the overall value chain for fundamental developments, planning, simulating, optimization of manufacturing engineering and training using artificial intelligence in the context of the heavy machinery and industrial sites as well as exploitation of these leading-edge developments locally and exporting those internationally as a part of the complex value propositions: end-product or services. With these partners, covering the whole value chain, the Finnish consortium can develop the core concepts, software modules, simulation tools with major features needed for simulating ergonomic human motion alongside the manufacturing value chain.

Tactotek

Tactotek is a global leader in injection molded structural electronics. Tactotek customers operate in automotive, IoT, wearables, appliance and medical sectors.

Dark Ambers Softworks

Dark Amber Softworks has designed and developed virtual reality training environments for railroad industry (KRAO) and heavy industry (Pöyry Oyj), and VR/Mobile-VR/WebGL applications for healthcare industry (Medi-IT Oy) and the city of Kouvola. In AIToC, the focus is on defining a framework to code elementary AI and simulate behavior through different pre –defined behavior state with another added level of character consciousness. Dark Amber Softworks' focus is on extraction of knowledge and process information from experience and data.

Lappeenranta-Lahti University of Technology (LUT)

LUT University is the leader of the use case in Finland, collection and integration of the requirements, lead the real-time and real-world simulation tasks, Finnish consortium coordinator, active contributor in dissemination & exploitation activities through scientific and industrial conferences participation and leading the business model development activity.

MeVEA

During the project Mevea will work on the implementation of AI support in their own software. Mevea will utilize results from the project to extend human simulation capabilities in their simulation tools. Mevea will also provide technology for real -time modular simulation tools required by other partners.

Process Genius Oy

Process Genius will work on the interface development to account different company department access to the digital twin and customize the interface to improve effectiveness. Process Genius has already development of digital twin software, where the real -time performance can be observed. In the proposed project, Process Genius will further develop the software for different stakeholders.

Raute Corporation

Raute has already developed a real-time simulation model of their products. These have proven to improve the current products and speed-up development projects. The AIToC project will allow to reduce complexity of virtual model creation and therefore, free up resources for other development tasks. It will also reduce time required for preparing tutorial videos and documentation for all the new products.

Sweden

The Swedish consortium is composed of a mix of partners from universities, research institutes, SMEs, suppliers and vendors, and OEMs, supporting the overall value chain for manufacturing engineering in the automotive and similar type of industries.

Volvo Group

The Volvo Group is one of the world’s leading manufacturers of trucks, buses, construction equipment, drive systems for marine and industrial applications, and services. In the AIToC project, Volvo will focus on developing initial requirements and provide inputs to concepts and solutions, as well as relevant data for use cases to demonstrate how a future efficient manufacturing engineering tool chain can be applied.

University of Technology Chalmers

Chalmers, within the automation research area, conducts a wide range of research in industrial methods and tools. The focus is mainly on planning, optimization, supervision and control of production systems, especially discrete event and logical systems, where complexity and information integration are two main challenges. Artificial Intelligence is becoming important and is highly relevant in this application area. Through Chalmers AI Research Center (CHAIR) a broad competence and experience is available and will be utilized in the AIToC project.

Fraunhofer-Chalmers Research Centre for Industrial Mathematics

The Fraunhofer-Chalmers Research Centre for Industrial Mathematics (FCC) is offering contract research, services, algorithms and software based on advanced mathematics within Modeling, Simulation and Optimization (MSO). In AIToC, FCC will contribute with research and development within modelling and simulation related to layout planning and optimization.

AFRY

AFRY (formerly known as ÅF) is an engineering and consulting company with assignments in the energy, industrial and infrastructure sectors. During the last few years, the company has put significant efforts to integrate engineering methods and functionality of simulation tools, especially to achieve full virtual commissioning. Their experience and knowledge will be important for the integration of tools in AIToC, to realize the use cases and demonstrations.

ABB

ABB is a word-leading manufacturer of industrial robots and robot systems and can provide state of the art automation knowledge to the project, especially virtual models that represents the true behavior of equipment’s in a production system. With the combination of Artificial Intelligence methods to fine tune models with data, and deep knowledge of the equipment and their control systems, they have capabilities to make optimized, trained and programmed virtual devices.

Algoryx Simulation

Algoryx Simulation is a leading provider of software and services for visual and interactive physics-based simulation. Algoryx have designed and developed a next generation physics engine with fidelity, performance, functionality and extensibility that surpasses all comparable solutions on the market. Their contribution will be particularly important for the creation of the models and simulations of processes and resources.

Solme AB

Solme AB develops software tools and provides services for industrial engineering. This includes methods and tools for effective analysis of manual assembly processes, by combining video analysis with time and motion studies, visualization and optimization of line balancing from the aspects of time, ergonomic stress, material access and operator work zone. Solme AB will contribute with competence and tools for data acquisitions and how to make use of the AIToC approach for process and operations planning to generate information and visualizations that will be used in production.

Univrses

Univrses is a fast-growing start-up company with a highly qualified team of scientists and engineers within computer vision and machine learning as key competence. One key area is 3D computer vision creating and delivering technologies for 3D Positioning, 3D Mapping, 3D Localization, Spatial Deep Learning and Sensor Fusion. Their competence and products can be used in combination with physically based methods to create more complete and realistic system models for both geometry and function.

Turkey

Turkish consortium has been positioned as a complete value chain sub-consortium which covers all the work packages and provides integrated exploitation scenarios from Turkish automotive industry. The consortium includes two use- case providers and four tool and service provider partners, which are led by Eryaz Software.

Ford Otosan

Ford Otosan is an automotive manufacturing company which has achieved 9 consecutive years automotive industry championship. The company has the biggest E&d organization of the Turkish automotive industry with a production capacity of 455,000 commercial vehicles, 70,000 engines and 140,000 powertrains by the end of 2019. In AIToC, Ford Otosan will provide use-case on the AI-based analysis of the machining lines.

TOFAS

TOFAS is an automobile manufacturer which manufactures passenger cars and light commercial vehicles with 450,000 vehicles annual production capacity. TOFAS will provide use case on the simulations and decision-making support for constructing the production systems. TOFAS will also provide support for work package that is concerned with the product design.

UNIT R&D

UNIT R&D will bring its extensive knowledge and experience on the model-based systems modeling and analysis that they gained during their previous and present ITEA research projects. So, UNIT will provide high expertise covering project innovations in automated analysis of requirement engineering models of manufacturing and product engineering. UNIT will also support the project for the dissemination of the works done via the relevant well-regarded conferences and journals.

ARD Group

ARD Group will use their expertise on different artificial intelligence (AI) techniques (e.g., optimization, expert systems, and machine learning) that they have gained from their past and present research projects. ARD will provide support for the AI -based tool developments in the project, which make them involved in several work packages. These include the tools that apply different AI techniques for selecting the optimum manufacturing process plan among all the alternatives existing, optimizing the layout in factories for manufacturing the modeled products, and generating the optimum production resources for the modeled products.

Ericsson

Ericsson will collaborate with Eryaz on developing the AI-based tool for collecting factory data at real-time and simulating them. More importantly, Ericsson will provide the tool developments for the visualization of the data resulted from the AI-based tools and the integration of the tools developed.

Eryaz Software

Eryaz Software will act as the national coordinator and be responsible for developing a modeling language and toolset for the requirements engineering. Eryaz will also contribute to the development of an AI-based tool for collecting real-time data from the factory and simulating them and the disseminations of the works done by preparing the journal/conference papers on the products/technologies proposed.

Use cases

The AIToC project goals are built on top of four use cases, Heavy Truck Manufacturing (Volvo): Planning, optimization, visualization and simulation of hybrid assembly systems, Car Manufacturing (FordOtosan & TOFAŞ): Using AI Techniques for Analyzing Machining Lines Data and Constructing the Production Systems, Bus & Coach Manufacturing (Daimler Buses): Process Planning, Process Simulation and Operator Assistance and Production Equipment Manufacturing (Tactotek): AI-based design of production equipment for automated plants.

Bus assembly - Daimler

Within the Bus & Coach Manufacturing Use Case a modular and flexible system for the information provision in manual processes will be worked out. Based on results of semi-automatic generation of manual worker processes of the ITEA-project MOSIM AI-based methods will enable a context-aware operator assistance.

Truck assembly - Volvo

The scope for the use case is sub-assembly of components for e.g. truck chassis or powertrains. They are typically built in many variants and the assembly area includes a number of stations, including nearby kitting and material supply. There is a “main flow” of connected stations and the material supply comes from different directions and in different forms. The processes are manual, automated or with automated support, e.g. human-robot collaboration in “hybrid system”. The main goal of the use case is to demonstrate the AIToC approach, starting from product and production system requirements, to do the assisted process planning, selection of tooling and equipment and layout optimization of the system. Different alternative solutions should be evaluated and demonstrated using relevant visualizations and simulations to validate the method.

Disk brake manufacturing - Fort Otosan

Ford Otosan will create a digital twin of the (to-be-established) brake disc manufacturing line after the knowledge creation from an operational manufacturing line. On this digital twin platform, a user interface will be designed and developed. It will collect and store real-time sensor data from the production environment. A separate data storage system and server will be used. An AI support to analyze real-time data collected from the sensors will be provided. The project content will enable further predictive maintenance study to be carried out of the proposal content.

Smart molded structures - Tactotek

Tactotek is an IPR company selling licenses for the molding/printing technology that can be used to create modular electronics; example plastic panel integrated AC touch controllers in electric cars (reduces weight and material needs). Company itself has an small production unit (that is mostly used for testing and presentations), main focus is on licensing technology to customers based on their needs. In AITOC project they are developing production simulation tool, in which the data inputs and machine calculation (AI) is used in designing and optimization of sold production process solution.

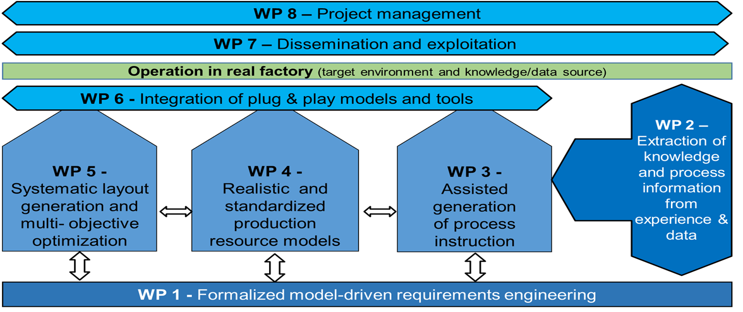

Project structure